Predictive Maintenance

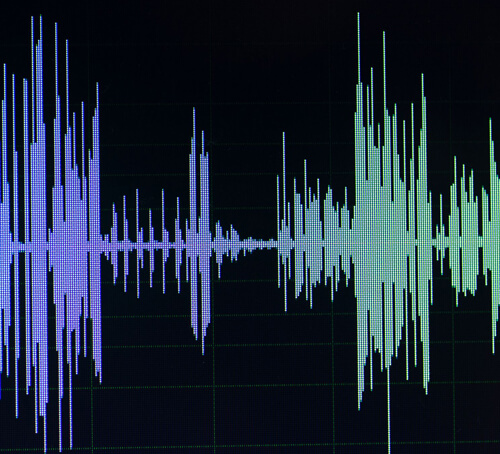

Ultrasound Monitoring & Analysis

Monitoring bearing condition through ultrasonic shows us evolving trends in friction levels, random impacting, rubbing, spalling, and other defects at the earliest stage of failure. In most cases ultrasound analysis will reveal the onset of failure long before they show up in vibration analysis reports and thermal imaging surveys. Ultrasound is especially useful for slow speed bearings and machines that do not rotate.

CMB for

DC Motors, AC Motors, Gear Reducers, Low Speed Rotating Machine, Pumps, etc.

Accoustic Lubrication

An inspector can be completely in tune with the sound of his bearings and over time can tell by sound quality, decibel levels, and time wave from analysis that the bearing needs lubrication and maybe entering early failure. This can prolong the bearing life by ensuring the correct amount of grease to lubricate the bearings.

Save up to 95% of grease usage

DC Motors, AC Motors, Gear Reducers, Low Speed Rotating Machine, Pumps, etc.

Vibration Monitoring & Analysis

Inspector measures vibration in 3 directions. (Horizontal, Vertical, Axial) Each direction able to indentify the root causes of the rotating machines vibration problems. This is an effective method to prevent any further mechanical damages of the machines. Corrective actions can be taken immediately to maximize machines service life.

CMB for

Blowers, Exhaust Fans, Impellers, etc.

Thermography Inspection & Analysis

Thermography is a powerful maintenance tool to identify overheating electrical & mechanical components by showing images of radiation to allow to see variations in temperature. Temperature can be measured from distance without contacting an object.

CMB for

Power Sources, Incoming Switchboards, Bearings, Transformers, etc.

Motor Current Signature Analysis (MCSA)

MCSA is based on the principle that an electric motor driving a mechanical load acts as a transducer. The motor senses mechanical load variations & converts them into electric current variations are transmitted along the motor power cables. Analysis of the current amplitude can be trended over time to provide an early warning of machine deterioration or process alteration. Analysis involves, incoming voltage, current, current / frequency response, winding resistance, winding inpedence, winding inductance, power quality, power factor, input power, reactive power, apparent power, phase angle, insulation resistance, all types of motors rotor eccentricity, cracked, broken rotor bars, casting voids, poor connections, cable faults, motor efficiency & power analysis.

CMB for

HV, MV Motors, DC Motors, Rotor Faults, Winding Faults, etc.

Compressed Air Leak Control & Analysis

Compressed air leak is the most common found in manufacturing plant. Energy consumption for producing compressed air is one of the highest in plant. On average, it represents 35% of the energy cost due to compressed air leak in manufacturing plant. Convert the wastage into profit by fixing the leaks!

Bearing Friction Monitoring & Analysis

This approach involves continuous monitoring and detailed analysis of bearing friction within machinery systems. By employing advanced sensors and analytical techniques, this method identifies deviations in friction patterns, which could indicate potential bearing wear or faults. Early detection allows for proactive maintenance interventions, minimizing downtime and preventing costly breakdowns.

Motor Circuit Analysis (MCA)

MCA is a comprehensive diagnostic technique used to assess the health and performance of electric motor circuits. It involves detailed examination of various parameters such as voltage, current, impedance, and insulation resistance within the motor circuitry. By interpreting these data, MCA helps identify anomalies, such as loose connections, insulation degradation, or winding faults, enabling preemptive maintenance actions to prevent motor failures and optimize operational efficiency.

Motor Energy Saving Project

This effort aims to improve the energy efficiency of electric motors through strategic upgrades and optimisation procedures. It requires doing an extensive assessment of motor systems to find energy waste and inefficiencies. This project intends to reduce energy consumption, operational expenses, and environmental effect by adopting solutions such as variable frequency drives (VFDs), motor rewinding, or motor replacement with high-efficiency versions while preserving or enhancing performance.

Steam Leak Control & Analysis

Steam is an essential energy source for many manufacturing processes. By boiling water in order to produce steam is therefore very costly. Leaks & steam trap failure might cost million of dollars annually!

Partial Discharge Test

Partial discharge testing is an important diagnostic processes for determining the insulation integrity of electrical equipment such as transformers, cables, and switchgears. In order to detect partial discharges—localized malfunctions within the insulation—it necessitates subjecting the equipment to controlled electrical stresses. This test detects and quantifies partial discharge activity, which aids in the identification of potential insulation deficiencies, imminent failures, and safety issues. Early identification enables preventive maintenance activities, such as insulation repairs or replacements, which ensure the dependability and safety of electrical systems.